Description

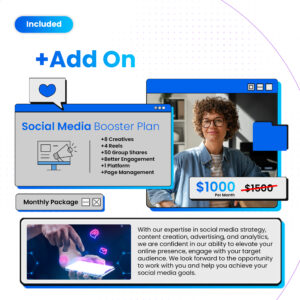

This is a Subscription based plan.

An Add-On Production Plan typically refers to supplementary activities or features that enhance an existing production plan. These “add-ons” can be tools, strategies, or modules integrated into the overall production process to improve efficiency, quality, and output. The activities covered by such an add-on can vary depending on the industry, software tools, or the specific needs of the company.

some common activities that may be covered in an Add-On Production Plan:

1. Forecasting and Demand Planning:

- Activity: The add-on can integrate with demand forecasting systems to help predict future production needs based on historical data, seasonal trends, and market demand.

- Benefit: Helps avoid overproduction or stockouts and aligns production with actual demand.

2. Inventory Management:

- Activity: Integration of tools for real-time tracking of raw materials, in-process goods, and finished products.

- Benefit: Reduces waste and ensures materials are available when needed, avoiding production delays.

3.Resource Allocation:

- Activity: Provides tools to allocate workers, machinery, and other resources effectively.

- Benefit: Ensures the right people and equipment are assigned to tasks at the right time, improving productivity and reducing bottlenecks.

4. Scheduling and Production Timelines:

- Activity: Adds functionality for detailed scheduling, including shift management, machinery utilization, and delivery times.

- Benefit: Optimizes production flow and ensures deadlines are met without excess idle time.

5.Quality Control Integration:

- Activity: Incorporates tools that monitor and ensure product quality during each stage of production.

- Benefit: Helps maintain consistency, reduces errors, and ensures compliance with standards.

6.Maintenance Management:

- Activity: Tracks machinery maintenance schedules and triggers alerts when equipment needs servicing or repairs.

- Benefit: Prevents unexpected breakdowns and ensures that machines are running at peak performance.

7.Cost Tracking and Optimization:

- Activity: Offers features for tracking production costs, including raw materials, labor, and energy consumption.

- Benefit: Helps identify cost-saving opportunities and manage budgets more effectively.

8.Supply Chain Coordination:

- Activity: Helps align production plans with supplier lead times, ensuring that materials arrive on time and that production isn’t delayed.

- Benefit: Prevents supply chain disruptions and optimizes sourcing.

9.Data Analytics and Reporting:

- Activity: Generates real-time data on production status, efficiency, and key performance indicators (KPIs).

- Benefit: Allows managers to make data-driven decisions, identify inefficiencies, and continuously improve production processes.

10.Risk Management:

- Activity: Incorporates risk assessments and mitigation plans for potential disruptions (e.g., supply chain issues, labor shortages, or equipment failure).

- Benefit: Ensures production continuity and preparedness for unforeseen circumstances.

11. Customization and Flexibility:

- Activity: Allows for custom workflows, the addition of new production stages, or integration with other business systems.

- Benefit: Provides flexibility for adapting the production plan to changing business needs.

12.Automation and Machine Learning Integration:

- Activity: Implements AI-based tools for predictive maintenance, production optimization, and automation of routine tasks.

- Benefit: Enhances efficiency by reducing human errors and automating repetitive tasks.

13.Collaboration Tools:

- Activity: Provides communication platforms or tools for collaboration between teams, departments, and stakeholders.

- Benefit: Promotes seamless communication and better decision-making across the production chain.

14.Environmental and Sustainability Initiatives:

- Activity: Adds features for tracking energy usage, waste management, and sustainability practices in the production process.

- Benefit: Helps businesses reduce their environmental footprint and comply with regulations.

15.Compliance and Documentation:

- Activity: Helps track industry standards, regulations, and certifications related to the production process.

- Benefit: Ensures compliance and facilitates audits.